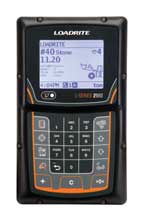

Loadrite L2180

Loader Scale:

CLICK HERE FOR

OPTIONAL LOADOUT MANAGEMENT SYSTEM

|

Loadrite redefines

accuracy with FACT (Friction and Ambient Compensation

Technology) with the latest generation wheel loader

scale L2180.

|

|

Improve profits:

Eliminate double handling of material by loading right

the first time; Avoid overload fines by ensuring trucks

are loaded to the correct value; Reduce haulage costs by

avoiding unnecessary trips caused by under loading.

|

|

Increase

Productivity: Prevent truck turnarounds at the

weighbridge, reducing cycle times; Sell more product

without adding equipment or personnel; Achieve

consistent loading from machine operators regardless of

experience.

|

|

Payload data can

be stored internally and/or printed for hard copy. For

comprehensive reporting and analysis of all Payload Data

the optional Material Management System can be used to

store data over longer periods. This data is easily

transferred to a computer for further processing.

|

|

The Loadrite L2180

can be installed on all makes and models of front-end

loaders and can operate with a high degree of accuracy,

even on a slope (with additional sensor). |

View L2180

literature for more details

Loadrite

LP950 Printer

Click here to

view sample print-outs

|

Add a Loadrite

Printer to your Loadrite Weighing System and get a hard

copy proof of each load. |

|

Printer tickets

deliver time-stamped and dated hard copies of weighing

information, including each bucket load and the total

load. |

|

The Printer is robust

and reliable with proven performance in extreme

environments. |

|

Company name |

|

Time

and date |

|

Machine identification |

|

Identification codes such as Customer, Site

Location & Truck/Docket Number |

|

Product identification |

|

Weight units (kg, ton, lbs.) |

|

Individual lifted weights |

|

Individual product totals |

|

Shift, daily or weekly accumulated totals |

|

Single or multiple copy paper |

View

LP950 literature for more details

Loadrite

LD947 Material Management System (MMS)

|

With Loadrite

Material Management System installed on your computer

you can turn your Loadrite Onboard Weighing System into

a sophisticated production management tool. |

|

Loadrite MMS allows

you to gather load data from your Loadrite system and

transfer it across your site in a secure, paperless

manner. You can also generate customized reports

based on loader, product, date, time or any other

combination of parameters stored in the database. What's

more you can transfer data into spreadsheet packages fro

further analysis and generating charts and graphs. |

|

Loadrite MMS helps

you:

|

Manage

product inventory |

|

Identify peak

loading patterns to improve your

business systems |

|

Eliminate the

need to enter data or process

transactions manually |

|

Confirm the

accuracy of information

originating from other sources

in your plant such as

weighbridges or production

machinery. |

|

View LD947

MMS literature for more details

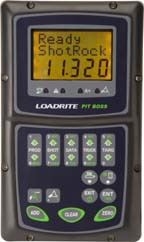

Loadrite

LR919 PitBoss

Pit Productivity Reporting Solution

|

The Loadrite PitBoss

is the first product to provide you with customized

productivity reports, generated directly from your pit

loader's weighing data. The PitBoss combines the ease of

use of our loader scale with powerful reporting software

giving you the visibility to monitor productivity

straight from the pit. |

|

Inventory control

straight from the pit: Track the tonnage of products

coming out of your pit by reporting on the amount of

shot rock, big rock, blending sand or other product

loaded into your haul trucks. Reports can be run by day,

week, month or preferred time period. |

|

Maximize haul truck

payload and verify haul truck capacity: Give the loader

operator the ability to see just how much material

they're loading into each haul truck. Make sure 55 tons

is being loaded into a 55 ton haul truck.

|

|

Increase loader and

haul truck productivity: Determine current productivity

levels for your pit operation by reporting on tonnage

per hour and cycle times of each loader and haul truck

working in the pit. This allows you to confirm whether

your pit operation is keeping up with your primary

crusher and make changes if necessary. Gain visibility

of the working hours for each loader and haul truck,

allowing you to confirm that operators are working the

required hours. |

View LR919

literature for more details

Loadrite LR913 Force

|

The Loadrite Force is

ideal in situations where you need accurate weighing but

you don't want the advanced features of product

tracking, batch or blending mode, volume conversion -

this just gives you the weight. |

View LR913

literature for more details

Loadrite LR911 Sprint

|

Loadrite Sprint is

best used on small loaders with less than 2 cu. yd.

capacity |

View LR911

literature for more details

Loadrite

Loadout Management System

Increased Communication

The

Loadrite Load Out Management System is designed to facilitate

communication between a quarry’s scale house ticketing system

and loader operators. Using radio modems and ruggedized in-cab

displays, loader operators stay informed of all trucks waiting

within the quarry, get confirmation of what type of product each

requires, how much product is required and how long the customer

has been waiting.

Improved

Productivity

You’ll also

gain total visibility of your load out operation, as it happens.

Through a large in-cab display, this information is available

for your loader operators, giving you the ability to optimize

truck throughput. If you can see what your loaders are doing,

you can better manage them and therefore increase their

productivity and reduce their maintenance costs.

Intelligent

Reporting

Every

movement of your machines and material becomes trackable,

turning the Loadrite scale system into a sophisticated

production management tool. With this valuable information, you

can monitor machine utilization, assess truck turnaround times,

better schedule your loaders and identify peak loading patterns.

Improved

Processes

The Load

Out Management System software provides managers with real time

information via a secure website. Selected information can be

made available through this site to contractors, regional

offices or key customers if necessary. The system also

eliminates the need to enter data or to process transactions

manually, which improves customer billing processes.

The Load

Out Management System is made up of:

A colored

in-cab display

A radio

modem for each loader

LMS

software which can be supplied on the Loadrite server

application or CD-ROM

A Loadrite

scale (if not already installed on loader)

Loadrite LR932 RoadBoss:

The intelligent Road Maintenance Solution

The Loadrite RoadBoss combines the ease of use of our loader

scales, with powerful reporting software that enables you to

manage your inventory and ease compliance reporting

requirements.

Loadrite's RoadBoss Material Management System (MMS) software

gives you the ability to capture load data either wirelessly or

by data module for further analysis. You can rapidly generate

reports from your PC, enabling you to track stockpile inventory,

report on product usage and compliance requirements and much

more.

View LR932

literature for more details

The Onboard Weighing

System for Excavators

|

Uninterrupted Productivity

|

The LOADRITE®

X-Weigh 2350TM

increases accuracy and productivity by giving

the operator a powerful tool to help improve

loading accuracy without slowing down the

operation of your excavator. |

|

|

Improved Profits

|

The LOADRITE®

X-Weigh 2350TM

ensures you load trucks to their maximum

capacity the first time, which lowers your

haulage cost per ton. You can also reduce under

and overloading which costs time and money. |

|

|

Unparalleled Support

|

It's LOADRITE's®

service and support that makes us

number one, and we're committed to staying

there. Our Authorized LOADRITE Distribution

Network delivers expert product knowledge and

support onsite. |

|